MANUFACTURE

MATERIALS AND PRODUCTION

Nowadays technology evolution allows to use a variety of materials in production of fountain pens, some of which, such as stone and wood, are certainly not suited to such an object. Once the choice was dictated by precise technical or economic reasons, only later stylistic aspects became important.

Acrylic resin.

Modern plastics have special qualities, depending on the type , such as unbreakability, flexibility and resistance to aging and light. In terms of their surface gloss and glowing colors, they are not at all inferior to their predecessors galalite, celluloid and bakelite. Acrylic resin is easy in production and polishing and offers a big assortment of colors and patterns.

Precious metals.

Gold and silver have been treasured since antiquity not only for their beauty. These precious metals also possess material advantages such as being malleable, workable and durable.

Gold does not corrode. In a pure state, gold and silver can not be worked. The metals are too soft for that. Therefore they are mixed with cooper, zinc, nickel and other metals. The proportion of gold is measured in karats.

24 karats means 1000 parts of gold.

18 karats = 750 parts

14 karats = 585 parts

8 karats = 333 parts

To offer a high quality precious object we produce 18 Kt gold nibs for all our pens.

Silver, almost as desirable as the more valuable gold, must likewise be alloyed,

usually with copper, to be usable for jewelry and writing instruments.

The usual silver alloy is sterling silver. It consists of 925 parts of silver and 75 parts of copper.

We use a solid sterling silver 925 on almost all our Limited Edition pens.

Ebonite.

Ebonite was the first material used for the production of fountain pens, in use since the first examples produced at the end of 1800.

By adding larger portions of sulfur and fillers, the soft raw rubber could be turned by vulcanization into an excellent product for the production of writing instruments: hard rubber, also called ebonite or vulcanite for the sake of elegance. The hard rubber, impervious the acid in the ink can be drilled, turned, milled, engraved and given a high polish with a mixture of oil and rottenstone. By adding suitable pigments ebonite can be made in ripple models that allow to produce an unique and unrepeatable patterns.Nowadays ebonite is rare and expensive due its completely hand made production. We offer a big assortment of colors and models made of ebonite material in Limited Series. We use a high quality certificate German ebonite material on all our pens. Fountain pens made of ebonite are completely hand polished and unique in their coloration.

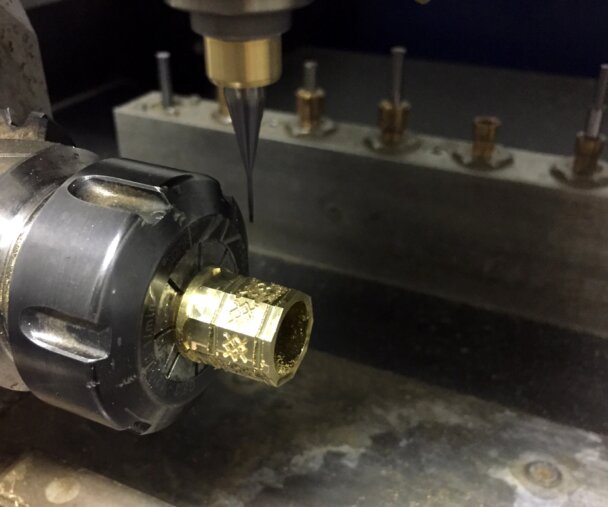

Diamond cut.

Diamond cut is an impressive name for a producer. It means nothing more

than the material - removing working on a plastic or metal tube with a diamond

as the cutting edge. The hardness of the diamond produces a faultlessly

smooth., highly polished surface that does not need to be polished afterward.

The diamond cut also makes artistic faceting possibly.

Polishing Technology.

The polishing step is a very important phase during the manufacturing process. It's important to know raw materials, parameters of application, tools employed and features of machinery in order to choose the right abrasive product for meeting the best result. Thanks to experience made during these years and our constant research and update we use a high quality abrasive products and technologies to reach the best result in polishing all kind of material.

We invest our resources and energy in new applications in the abrasive sector extending our range of materials in order to choose innovative products.

Thanks to the tests made and the continuous comparison of results, our know how is still growing, using always a new solutions during the finishing process of any kind of surface.

And a final step is always hand polishing, that gives a brilliant result and most performing appearance.

Ultrasonic Cleaning.

Ultrasonic cleaning uses cavitation bubbles induced by high frequency pressure sound waves to agitate a liquid. The agitation produces high forces on contaminants adhering to substrates like metals, plastics, glass, rubber, and ceramics. This action also penetrates blind holes, cracks, and recesses. The intention is to thoroughly remove all traces of contamination tightly adhering or embedded onto solid surfaces. Water or solvents can be used, depending on the type of contamination and the workpiece.

Dryer Technology.

Not many people know, but even drying system requires a lot of attention. To avoid unwanted shadows and halos after cleaning you need a proper equipment.

Industrial dryer system according to the principle of heat transfer, use steam radiator send out quantity of heat, through the air draft fan continuous suction and produce a heat cycle process, make the drum wind materials in a rotating drum ceaselessly inside turn positive and negative, and gradually drying.

Enameling.

Many of our pen elements are decorated with glossy enamel which is applied to the surface of a piece for decorative effect, depth and a shiny, durable finish. Enamelling is an art form in itself. Is the term used to describe a centuries-old technique of fusing a colored compound to a surface at very high temperatures, often between 80° to 120°C. This completely hand crafted technique allows to give a precious look to a ring, cap or a body of the pen and personalize the creativity of the object. In order to enamel properly, the element must be prepared, cleaned, polished and gold/silver plated. The enamel is applied to the areas needing coloration. depending on the design, this can be require a steady hand and meticulous attention to detail. After the enamel is placed into the surface, the element is sent to the oven to bake, usually at 80° for 2 hours, which cures the enamel and ensures that is hard and damage-resistant.

Ebonite feeder.

A feeder is probably the least important part in the aesthetic aspect of a pen, the feeder is actually the heart of the working of a fountain pen, and on a technical level it is probably the most important component of it. It is in fact the feeder that creates the delicate balance of forces that allows the correct passage of the ink from the tank to the nib that deposits it on the sheet of paper, and a fountain pen writes well because its feeder does its job correctly.

Why ebonite? Ebonite feeders are more expensive to make and require a more craft. To purists this is a part that has to do more with the correctness of the high level pen components, especially the one made in ebonite. Just to give you an idea, the ebonite feeder goes through 8 different machining steps, making the feeder itself a real piece of craftsmanship. While, the plastic ones, are simply made by injection molding, hence, mass produced even if their capillarity is more sophisticated.

Nowadays a very few companies produce their own feeders in ebonite and all of them are producing the nibs too.

Projects.

When you buy a Santini pen, you can be sure you are buying a product which is 100% made in our laboratory. From the processing of raw material to the manufacturing of the finished product, we take care of every single step at our workshops. The most sophisticated computer technology is combined with incredible manual skills, to give you a unique and exclusive product.